Service Page >

DM Laser-Fab have realised that success in today's sheet metal fabrication industry depends not only upon the ability to meet customer's current needs… but also upon the vision and strength to anticipate and respond to future changes in the marketplace.

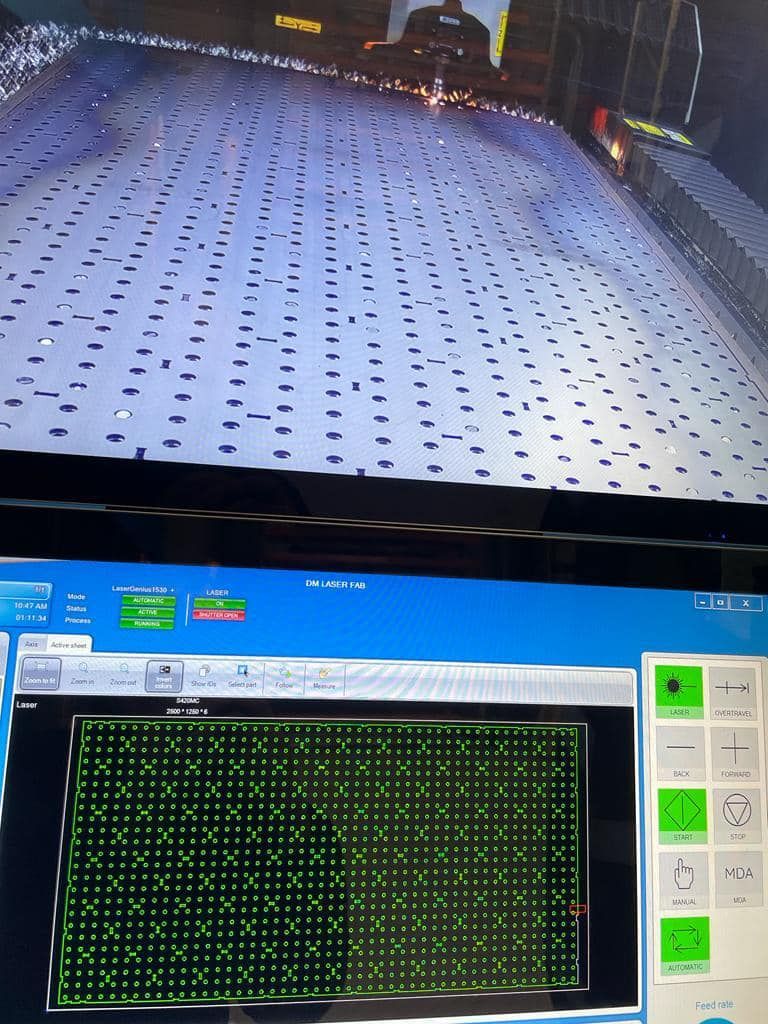

This is why the company have pushed the business forward with the installation to the factory of the new Laser Genius Plus. This machine is a breakthrough in sophisticated high-speed laser cutting for sheet metal fabrication, creating enhanced production with superior speed, accuracy, and part quality.

Laser cutting provides customers with the following advantages:

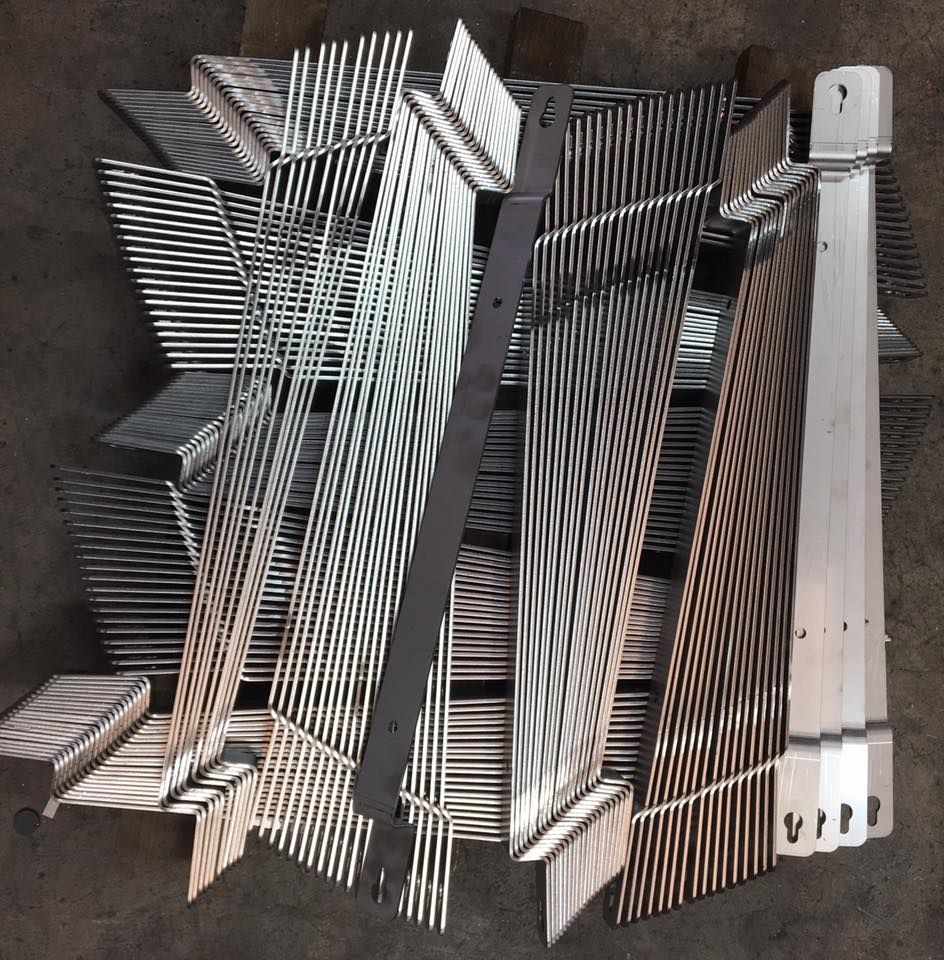

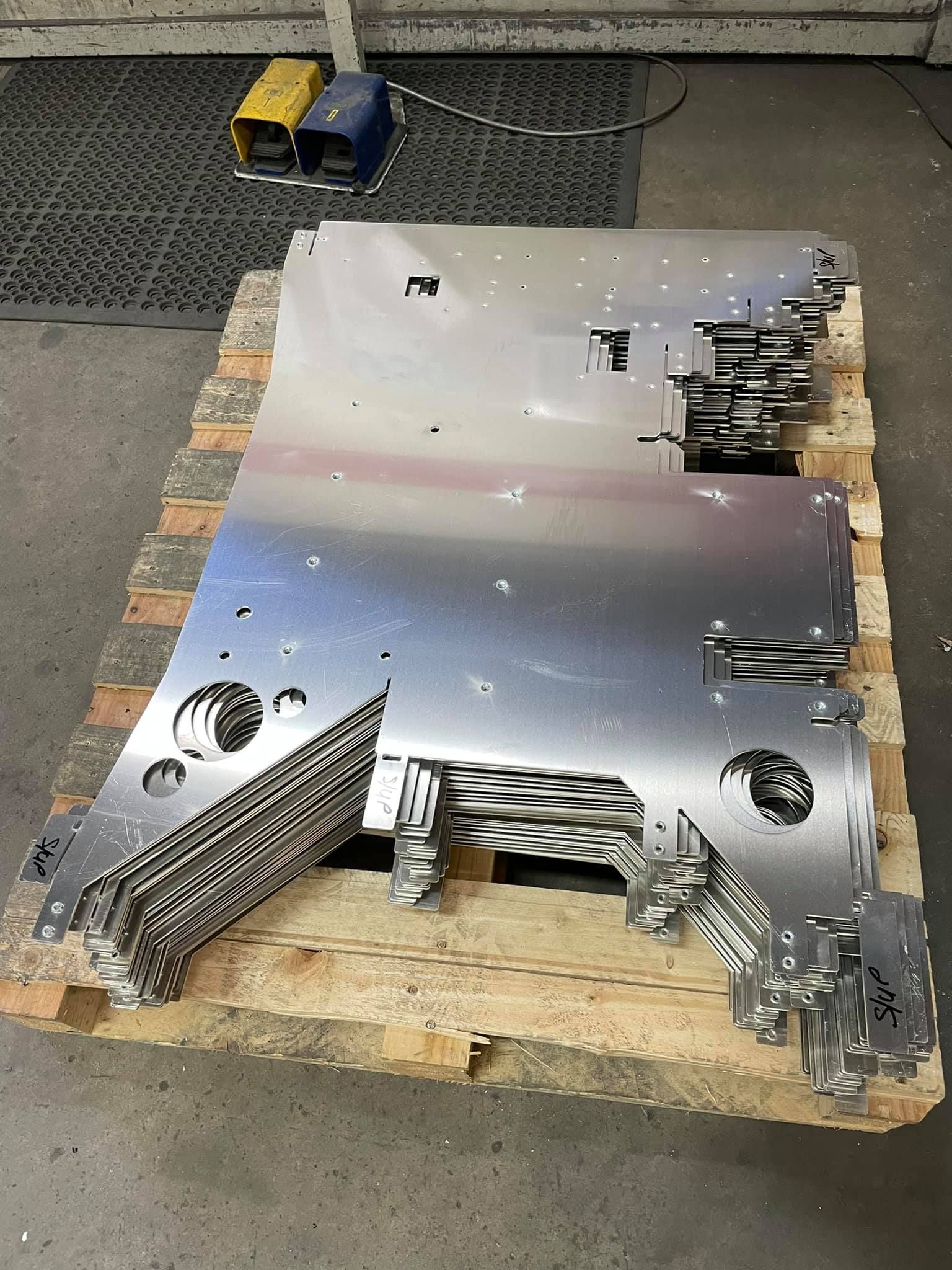

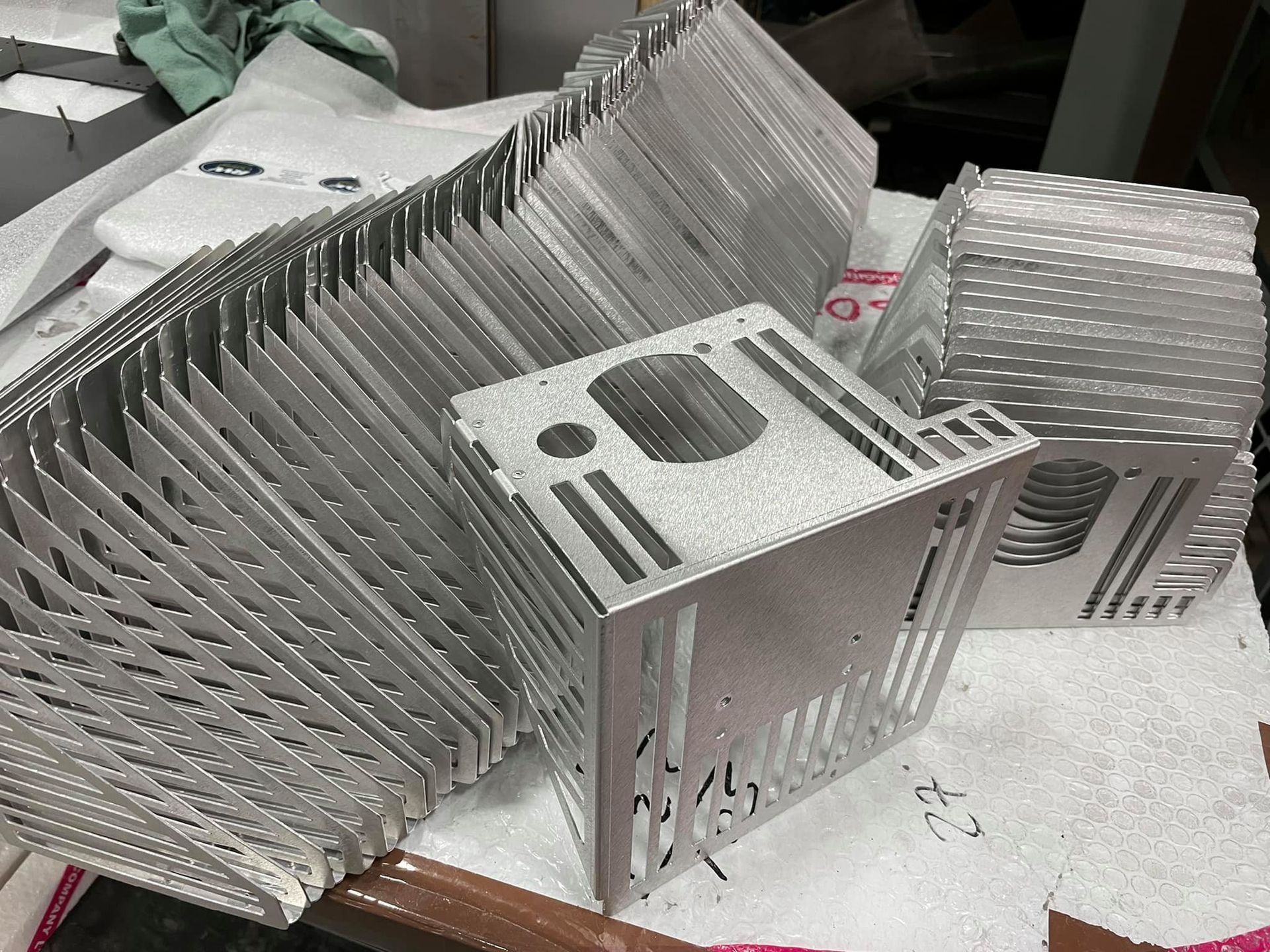

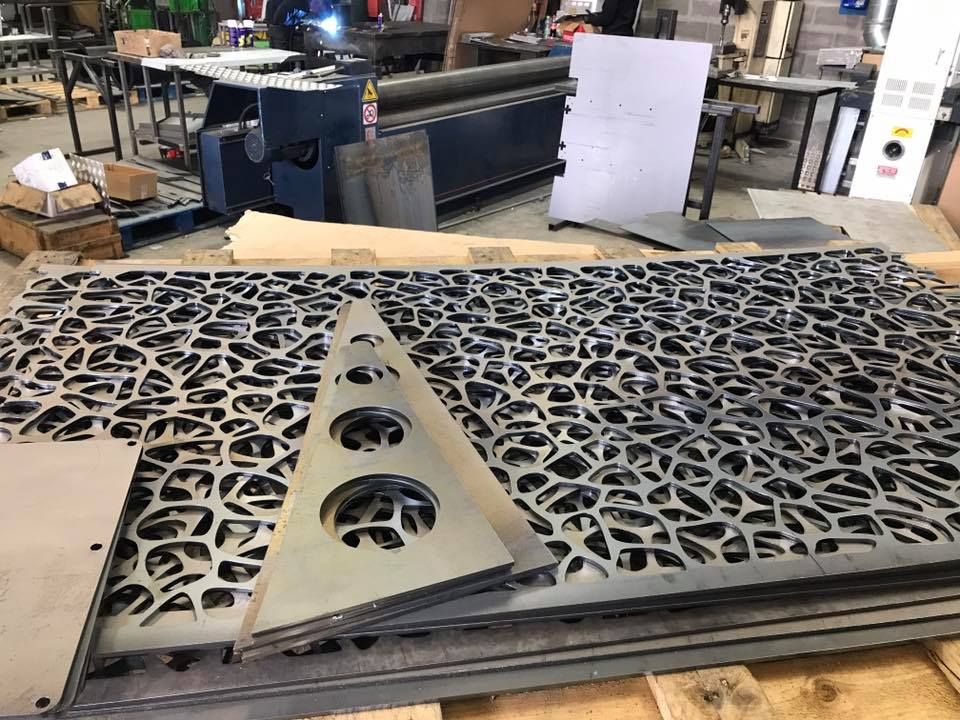

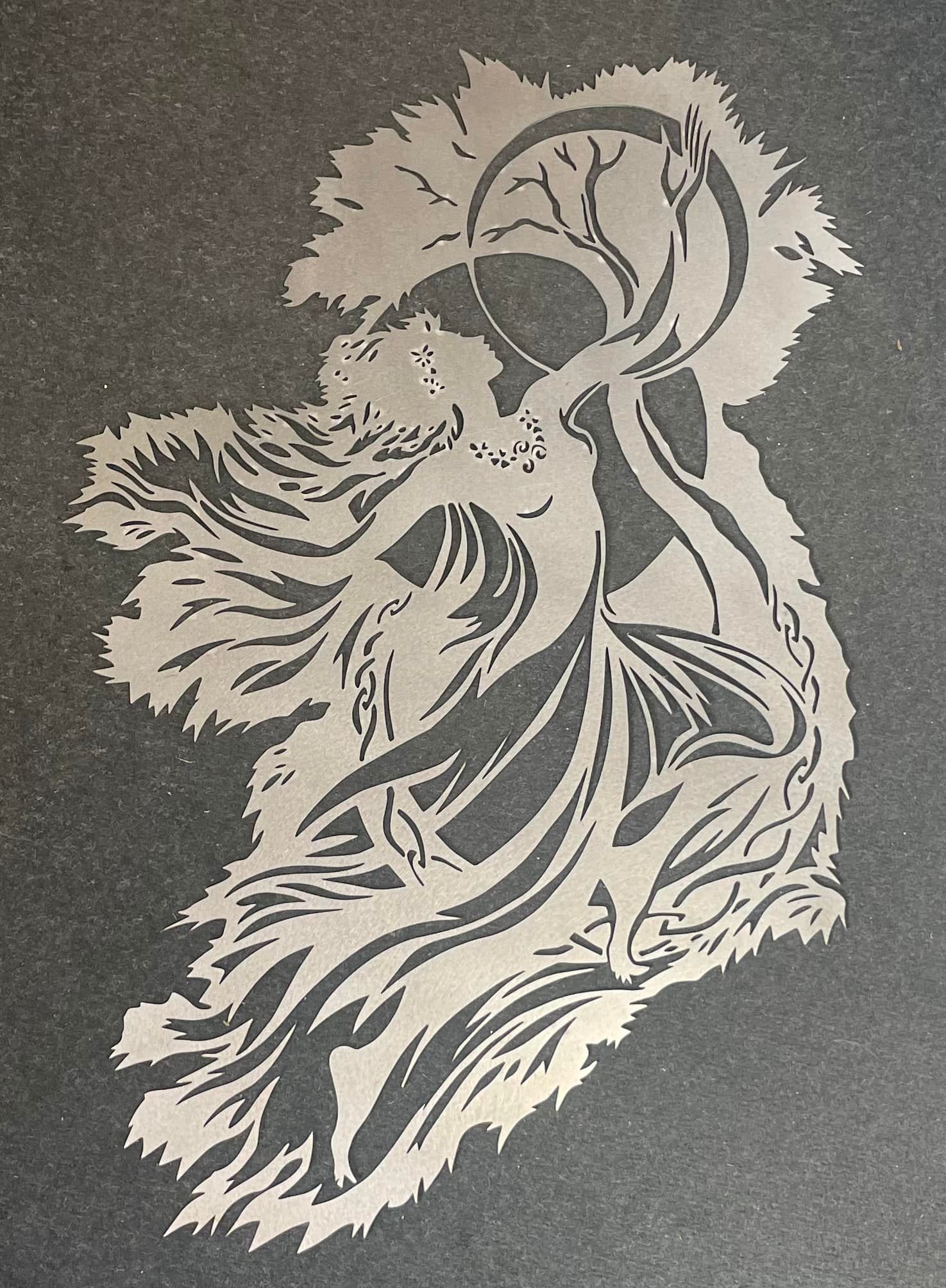

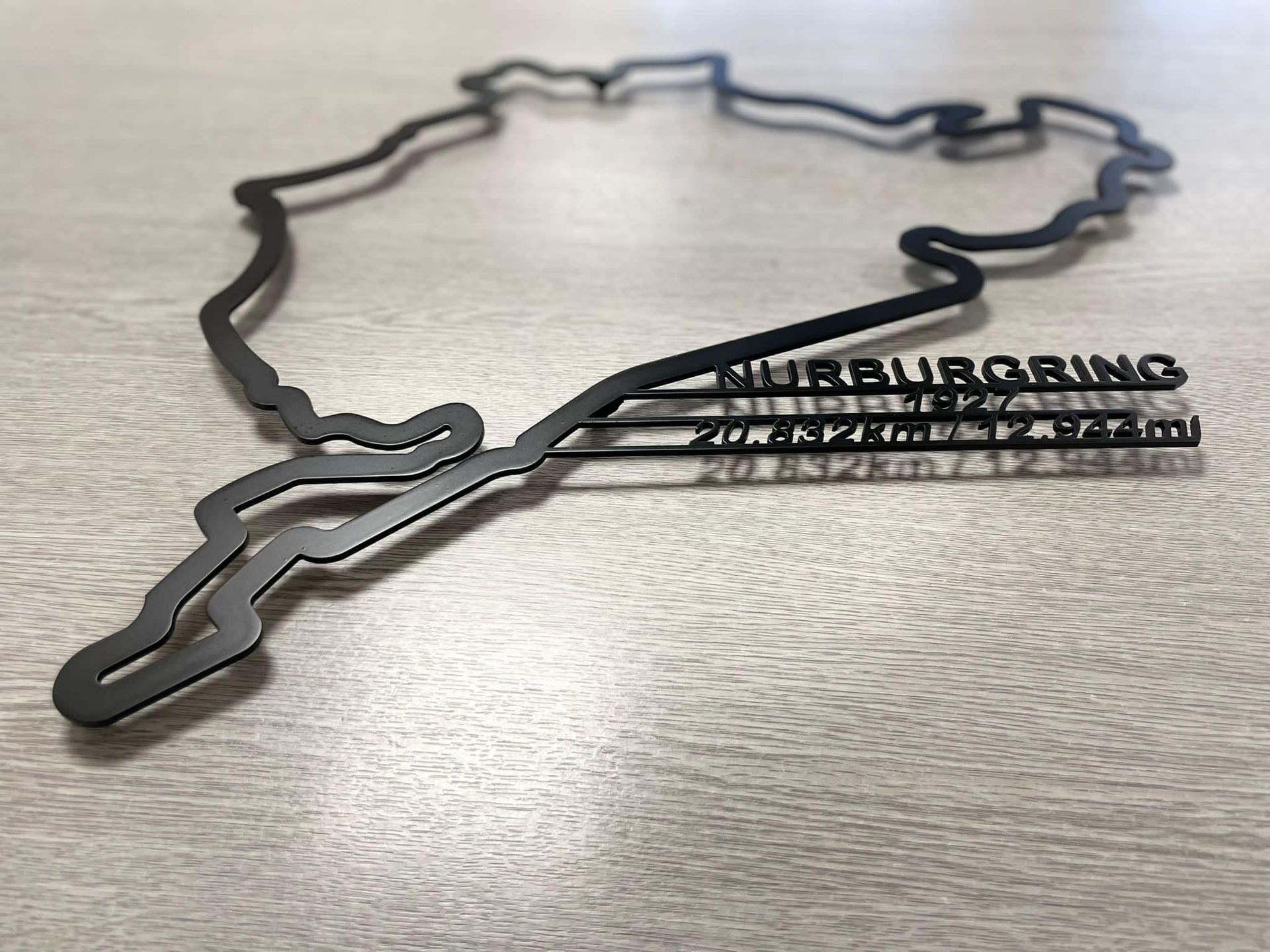

Consistent intricate and accurate shapes

Finished Product - no additional machining needed

Minimal wastage

Low set up costs

Minimal heat input

Rapid cost effective prototyping

Suitable for Stainless Steel (up to 10mm), Aluminium (up to 8mm), Mild Steel (up to 20mm), etc.

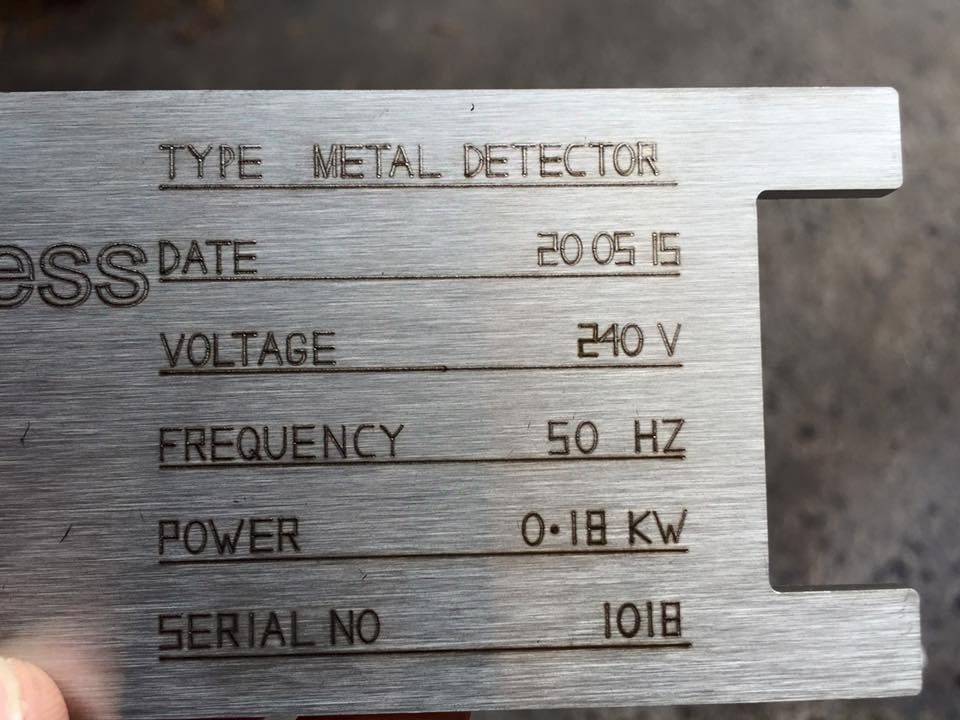

High pressure nitrogen cutting for stainless steel and aluminium alloys leaves a bright clean oxide-free finished edge, making welding of components easier without the need for further finishing. All components can be etched with logos or identification numbers to customer specification.

Unlike most other lasers we can cut Mirror polished stainless steels and steels that come with a protective polycoating. Tread or checker plates can also be cut

Laser cutting is not only a benefit to the sheet metal and engineering industries but also offers a whole new dimension to the sign making business. We have the ability to produce letters or full signs from stainless steel or aluminium to any intricate shape or design.

Precision Laser Cutting

Decorative Laser Cutting

Official Supplier to:

SEND US A MESSAGE

Reach out to us on email and one of the team will get back to you ASAP:

CALL US

Prefer to speak on the phone? No problem! Simply click the link below:

LET’S CONNECT

Jump over to our Social Media channels to catch up on all our projects & send us a DM if you'd like:

ONLINE QUERY.

Alternatively you can complete the following form and one of the team will reach out as soon as they become free: